Tom Senior Shapers & PlanersFirth Planer Senior Milling Machines Senior Lathes

Tom Senior, of Atlas Works, Hightown, Liversage, Yorkshire, England, began in trade by producing machines originally designed and manufactured by Arthur Firth of Cleckheaton. He also had a thriving business both factoring and manufacturing a variety of useful castings and tools designed to appeal to the model engineer, schools and technical-training institutions. Senior's range of products quickly expanded and, by the time World War Two started in 1939, a number of different drills, several varieties of shapers & planers in sizes 00, 0, 1, 2 and 3 as well as light-duty horizontal millers and a lathe were all available. The larger machines could be bought either as complete, working tools or in various stages of completion for final fitting and assembly by the purchaser. The shapers, planers and drills appeared not to survive the conflict and, by the time peace returned in 1945, Senior (who always operated from an almost cottage-industry site), was concentrating on his new range of horizontal, vertical and universal milling machines. There was also a close relationship between Firth and Hesketh-Walker, a Liverpool-based manufacturer or distributor, whose hand-operated planers appear to have been identical. However, who made what, and sold to whom, is not yet clear.Continued below:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|  |

|

|

|

|

|

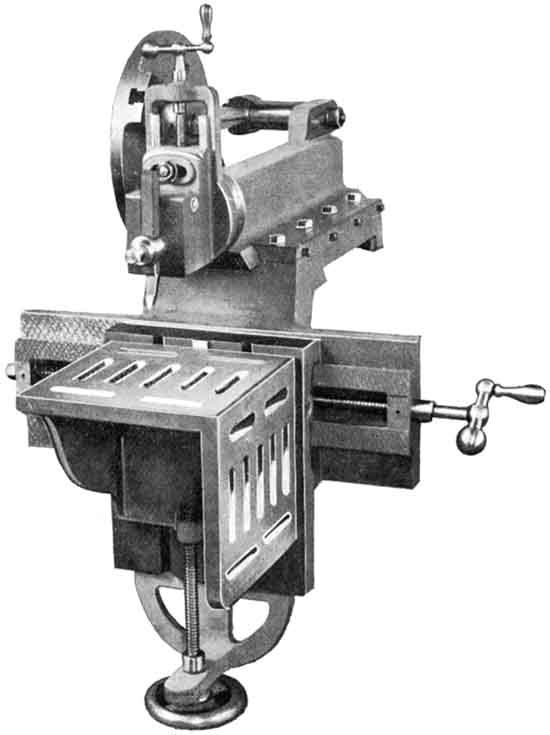

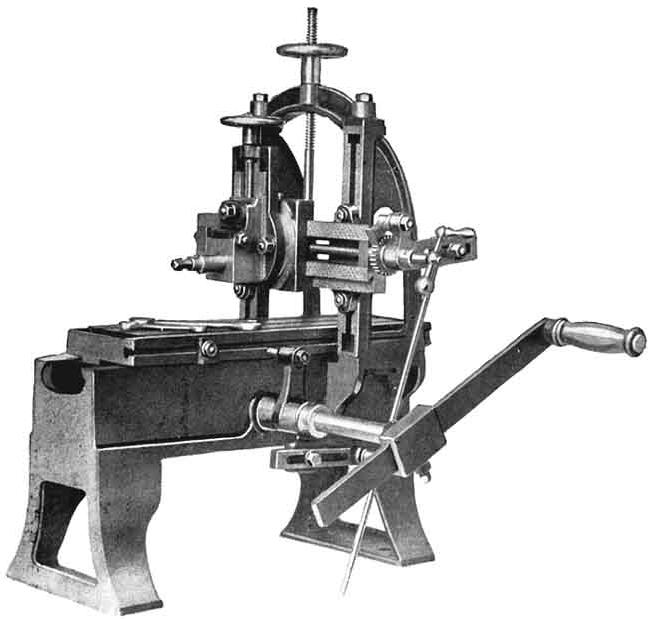

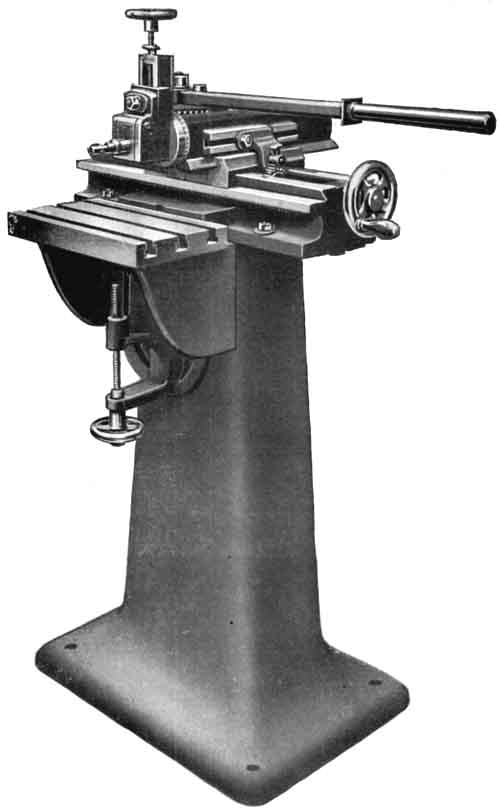

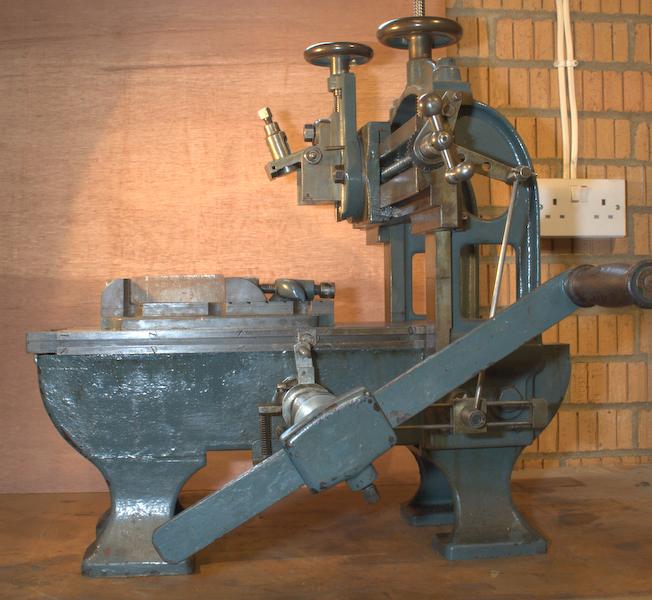

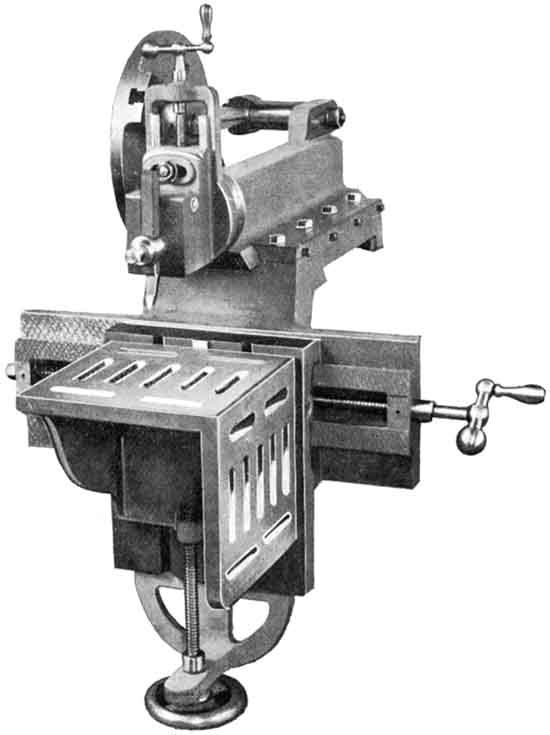

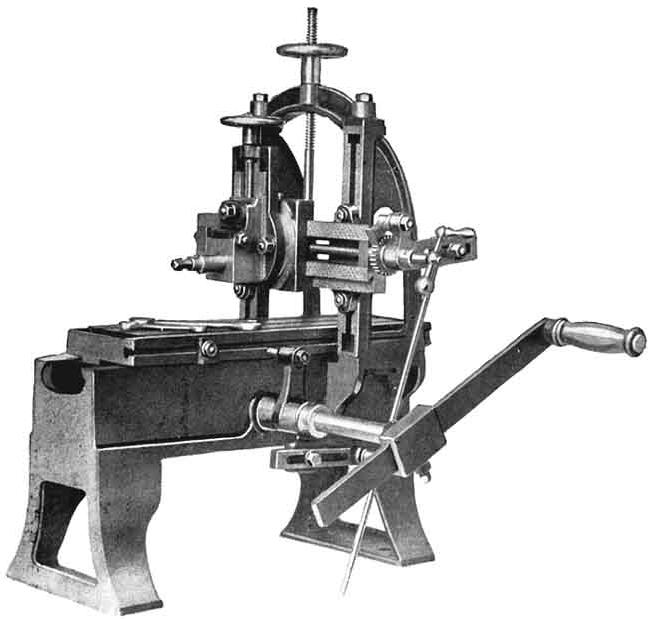

| Tom Senior No. 1 hand-operated shaper. This model was identical to the No. 2 (below) but in place of a T-slotted table, elevated by a screw, had a simple angle plate held by bolts passing through vertical slots into the knee bracket. The stroke of the ram was 8 inches and the cross traverse of the head a very useful 12.5" - this being much greater than that of the later powered machines of 10-inch stroke produced by Alba and Elliot, etc. The T-shaped "table" of the No. 1 measured 8" x 7" x 6.5" and could be adjusted vertically through a range of 4"; the maximum clearance between the table surface and a cutting tool was 9 inches.

In 1939 the complete machine was offered at £16 : 10s : 0d (about four weeks' wages at the time) or as a set of casting "in the rough" for £4 : 5s : 0d or "accurately planed" for £8 : 10s : 0d. - both prices including a set of blueprints.

Additional machining work could be carried out for the impecunious purchaser of the casting sets; turning the end of the ram and graduating and indexing it for angle work was priced at ten shilling (equal to a naughty weekend away in Blackpool); cutting the traversing and tool box screws and supplying threaded gunmetal nuts was fifteen shillings and, if the optional self-act to the head-traverse feed was required, a "machine-cut" pinion could be supplied (for the price of a Saturday of overtime in the mill) at seven shillings and sixpence.

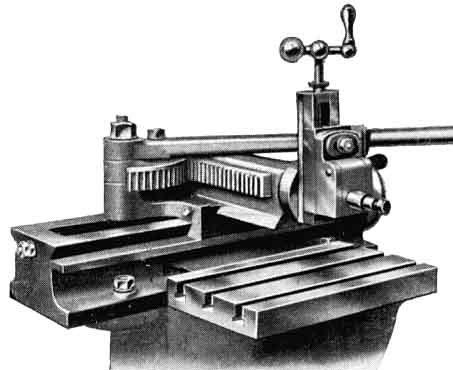

Both models were carefully thought out; the ram drive was by an apparently unique-to-senior rack and quadrant arrangement (but later also used on Perfecto shapers) and the body of the machine was cored with a two-inch diameter hole that allowed shafts to protrude through under the clapper box - and so enable a slot to be cut anywhere along their length.. The table and handwheel assembly could be detached from the body of the machine to reveal a machined and slotted vertical face that offered a further range of opportunities to mount special or difficult-to-handle work.

Besides these hand-operated shapers Senior also manufactured a shaper attachment designed to fit on the bed of a lathe - and take its drive from a slotted crank plate that bolted to the faceplate; details of this interesting device can be found lower down the page.Continued below: |

|

|

|

|

|

|  |

|

|

|

|

|

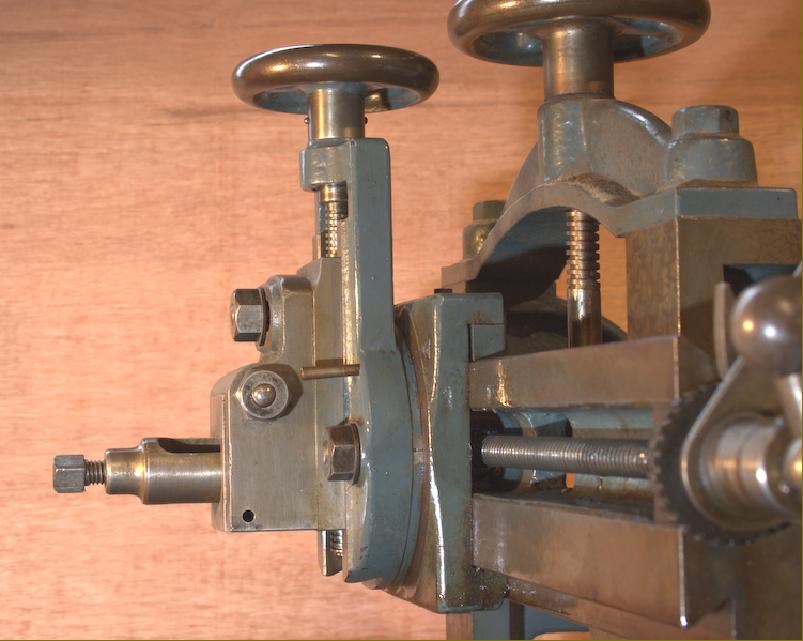

| Tom Senior "Shaping Attachment" designed to fit on the bed of a lathe and take its drive from a slotted crank plate bolted to the lathe's faceplate (note the dovetail ways on the rear support).

The slot in the crank plate (just visible in the illustration) allowed the length of the stroke to be adjusted.

Senior proved a range of popular fittings but could, on submission of a suitable sketch, make the unit to fit almost any section of bed.

The shaper was made in five sizes:

Size 1 Stroke 5" Traverse travel 8" to suit lathes of 3.5" to 4" centre height

Size 2 Stroke 6" Traverse travel 10" to suit lathes of 4" to 4.5" centre height

Size 3 Stroke 8" Traverse travel 12" to suit lathes of 4.5" to 5" centre height

Size 4 Stroke 9" Traverse travel 14" to suit lathes of 5" to 6" centre height

Size 5 Stroke 10" Traverse travel 16" to suit lathes of 6" to 7" centre height |

|

|

|

|

|

|  |

|

|

|

|

|

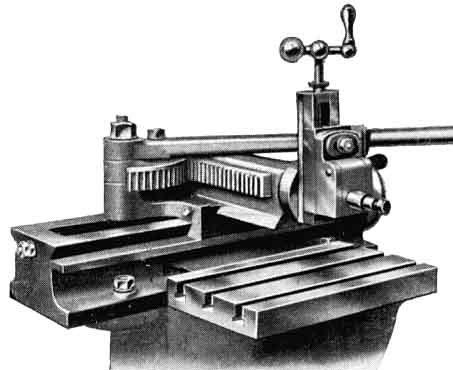

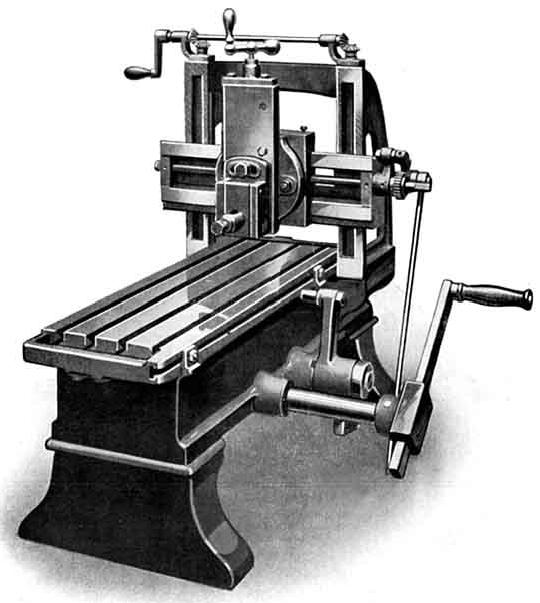

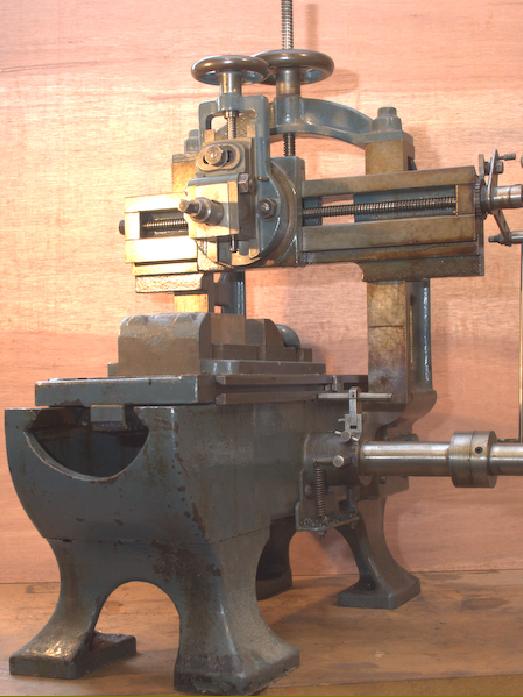

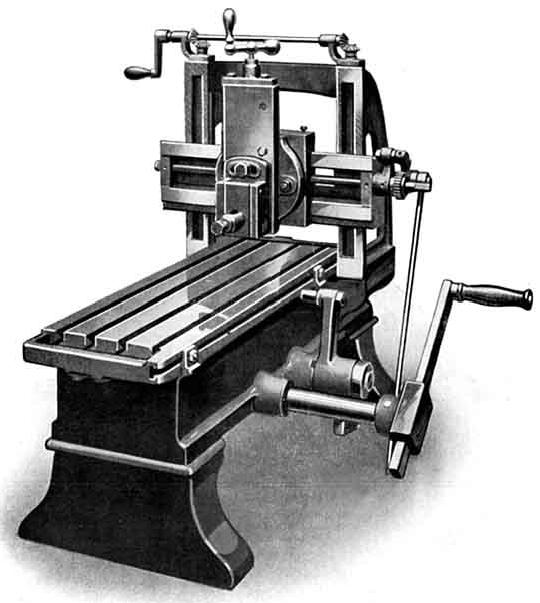

| Senior No. 2 Self-acting Hand Shaping Machine. Identical in size and capacity to the No. 1 the No. 2 featured a wider T-slotted table of 12" x 7" elevated by a proper screw and nut.

|

|

|

|

|

|

|

|

|

|

|

|  |

|

|

|

|

|

|

|

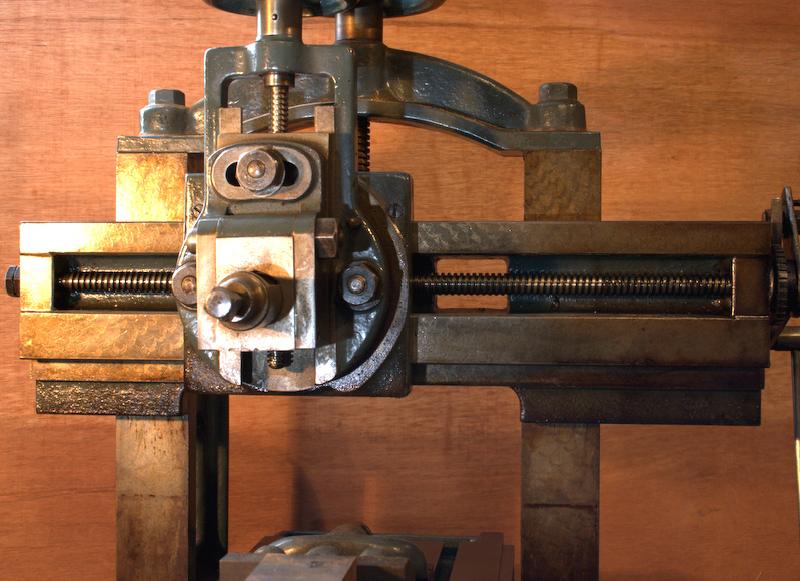

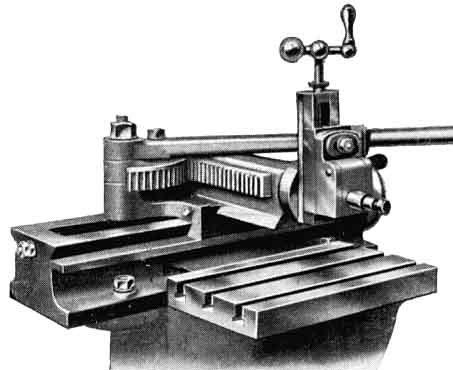

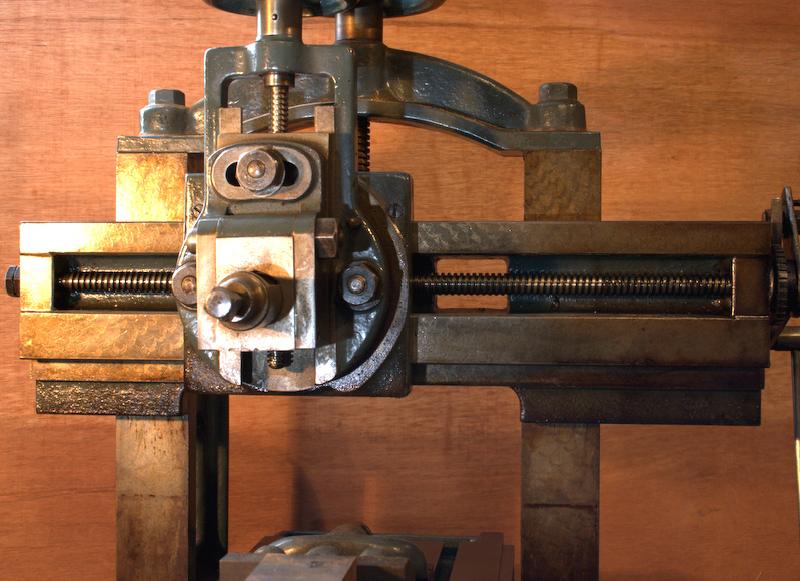

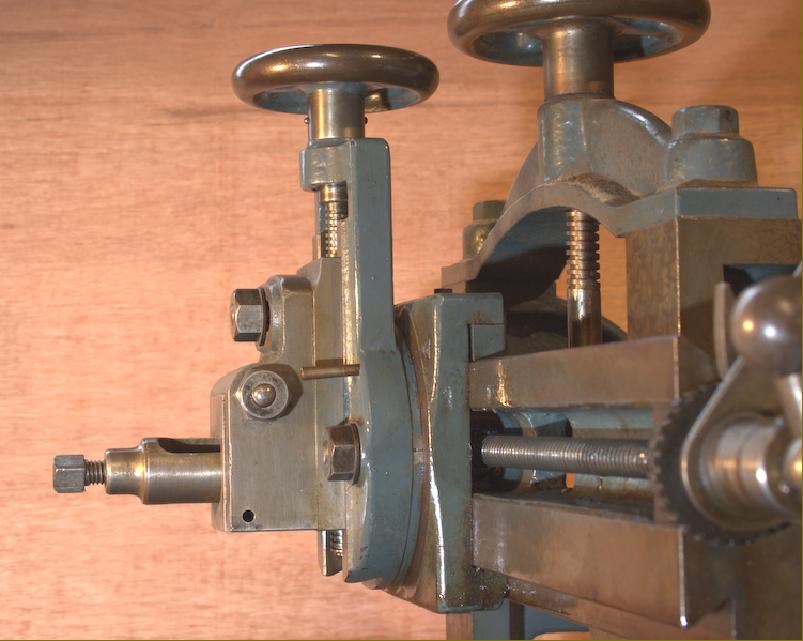

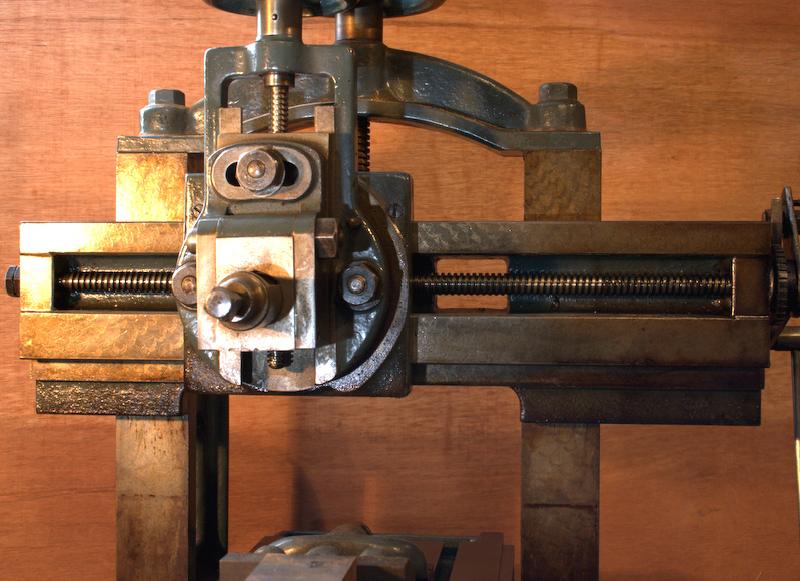

| The Rack and Quadrant drive - a feature that seems, at the time, to have been unique to Tom Senior |

|

|

|

|

|

|

|

|

|

|

|  |

|

|

|

|

|

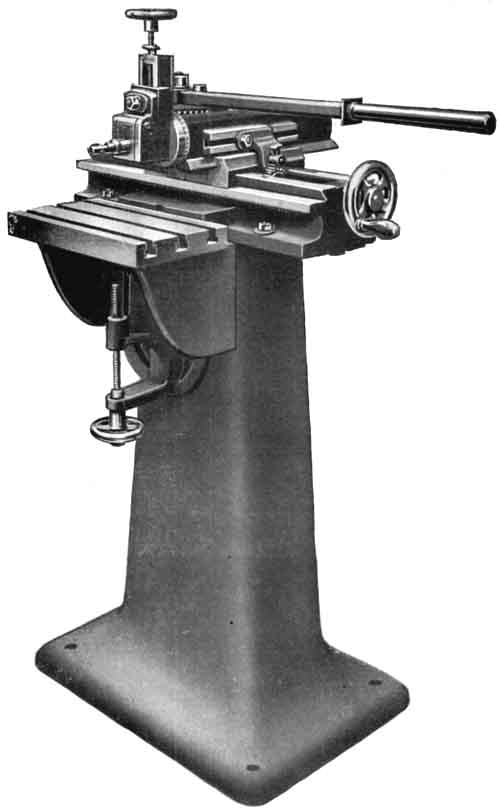

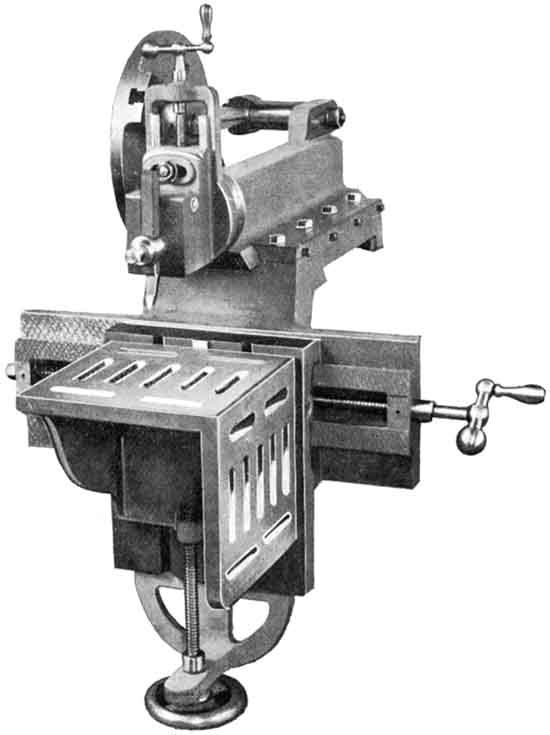

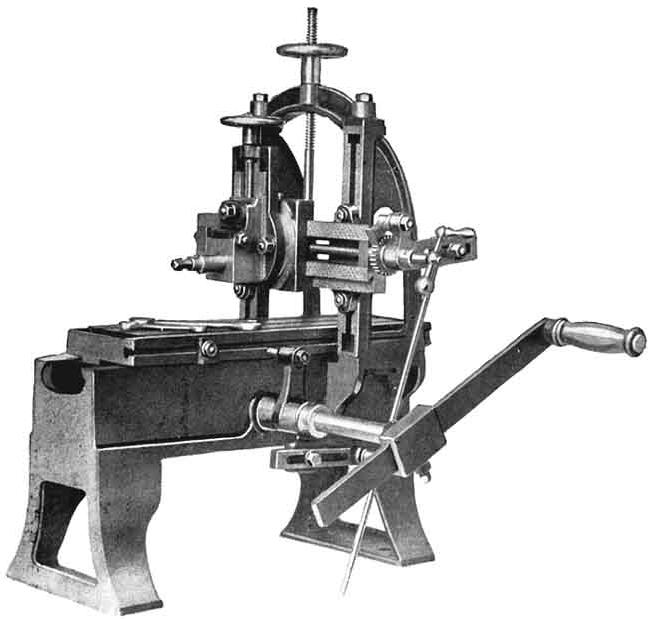

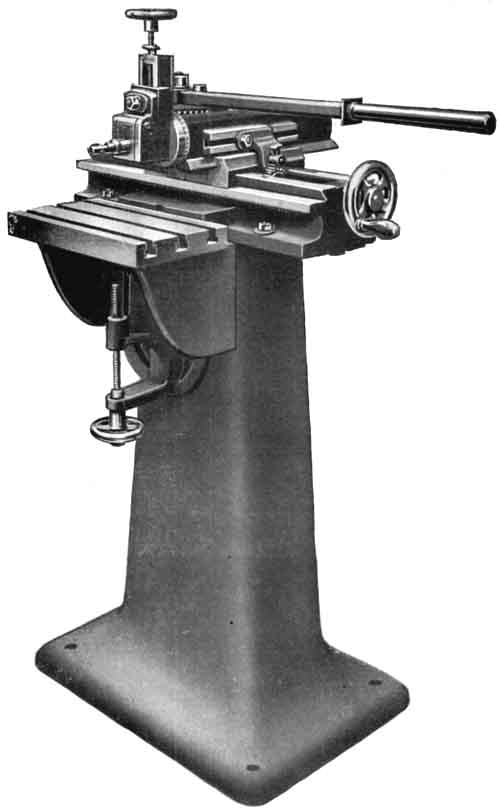

| Tom Senior Nos. 1 and 2 Planer with automatic cross feed.Continued:Today, unless they are located in a particularly remote area, without access to larger milling machine, planers are almost unknown in the workshops of all but the keenest and most knowledge amateur engineers. However, as a means of economically removing metal from large components they are still unbeatable and many massive examples, some the largest machine tools ever constructed, are still in industrial use. One particularly effective development is the "plano-miller" - a planer with powered cutting heads fastened to the bridge and uprights and able to perform miracles of metal removal on huge jobs.

Despite their rarity many enthusiasts still seek out the smaller versions - the bench job in particular are keenly sought after and command a high prices - and not just for their novelty, but to do a serious job of work at low cost. Although the delightful movements of a powered machine are a delight to behold, the hand-operated versions also provide an extra glow of pride as the owner enjoys the satisfaction of complying with the latest government health edict (issued, you may have noticed, by an overweight politician) on regular exercise and sin-free living.

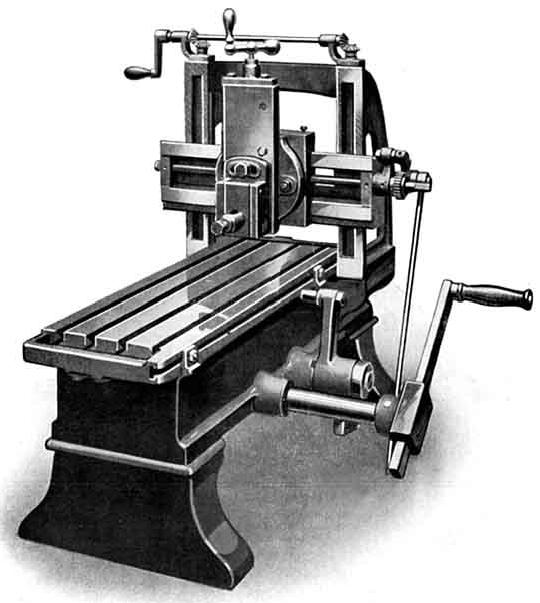

The Senior planers illustrated on this page, all from a more gentlemanly age (and almost certainly as originally produced by Arthur Firth of Cleckheaton) were available as either complete units - or as rough or planed castings. Five sizes were listed: 00, 0, 1, 2 and 3. No 00 could machine work up to 12" long, 6" wide and 41/2" high. The No. 0 took material up to 16" by 6" by 41/2"; the No. 1 18" by 7" by 5"; the No. 2 20" by 7" by 5" and the No. 3 24" by 10" by 7".

Whilst the No. 1 and No. 2 were essentially the same machine they did have tables of a different size - whilst the No. 3 was a much more robust model that must have been at the very limit for hand-powered operation.

Prices for the time were modest: the No 1, which could machine a component 12" long by 6" wide and 4.5" deep, was £15 : 19s : 0d with auto-feed (or without at a saving of £2 : 4s ; 0d) whilst the larger No. 2, with a 20" by 7" by 5" capacity, was £18 : 14s : 0d - or £15 : 8s : 0d if you wanted to apply the cross feed by hand.

In casting form the No. 2 and No. 3 machines were respectively £2 : 10s : 0d and £4 ; 0s : 0d in the rough - and £7 : 10s : 0d and £9 : 0s : 0d with the major components ready planed. However, it would have been a brave man who smuggled one of these through his kitchen, past his better half - and down into the garden shed for home completion..

|

|

|

|

|

|

|  |

|

|

|

|

|

| Tom Senior No. 3 Planer with self-act on the cross traverse. |

|

|

|

|

|

|

|

|

|  |

|

|

|

|

|

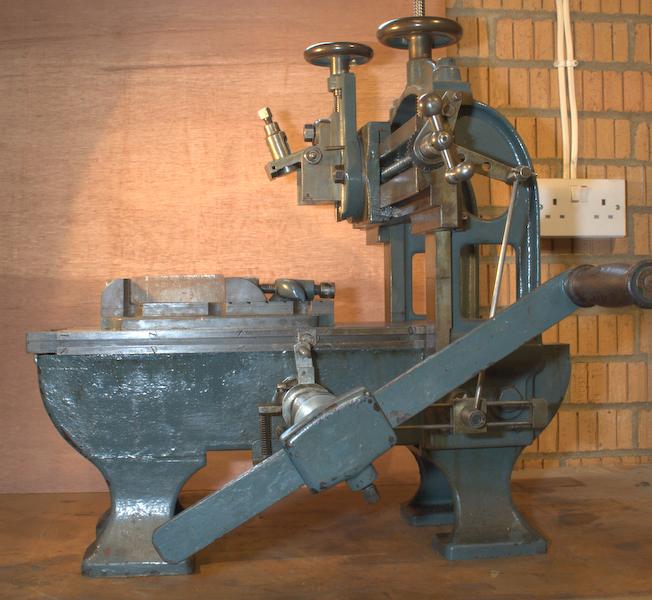

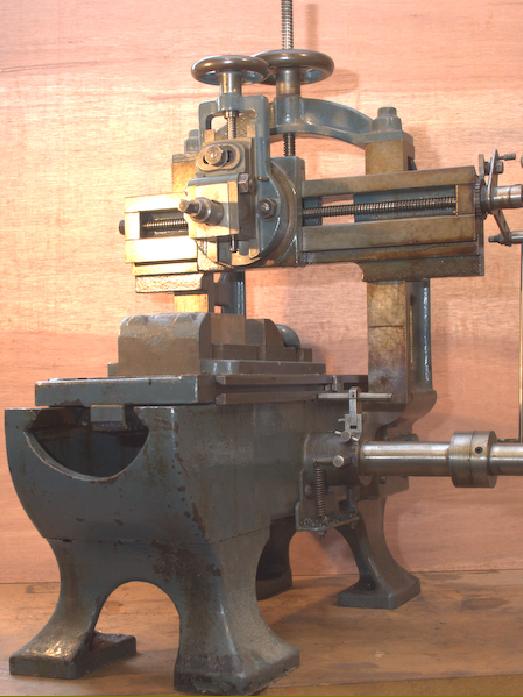

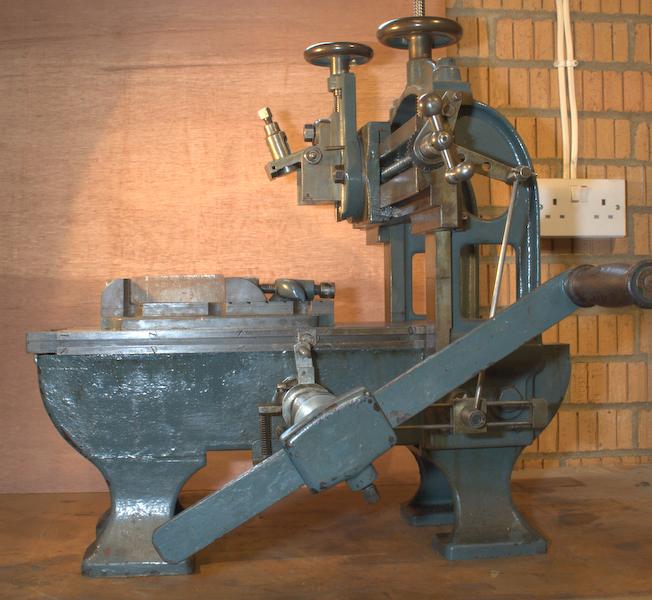

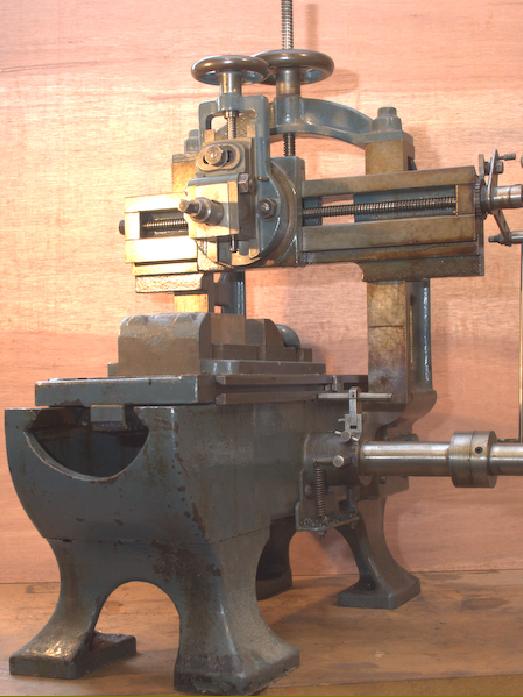

| More than likely by Arthur Firth, this diminutive model from their range probably dates from the first decade of the 20th century.

Despite it's small size, with just an 18" x 6" table and a maximum clearance of 6 inches between tool and top surface, this is a heavily-built machine and can only just be lifted by one man with the table removed.

Like most if its kind (and many shapers) the clapper box can be rotated a little each side of central to allow clearance on the return stroke when using certain shapes of cutting tool. However, not so common is the provision of a tapered pin to set the whole of the tool assembly vertical again if had been angled over.

Able to work in either direction - by flipping a pawl over - the cross feed rate can be altered by sliding the vertical actuating arm along the two parallel horizontal bars. The mechanism appears to be of a more modern design than the planer--and is interesting. The drive is tripped by an adjustable stop, set in a T-groove machined along the edge of the table, and by rotating the arm that hits the stop the mechanism can be set to feed at either the beginning or towards the end of the stroke. The component is hinged, and with a cut-away that allows it to 'fold' in one direction, yet remain upright in the other - so ensuring that the feeds mechanism operates in one direction only. However, as found, the device lacks a spring to return it to return to the upright position - and may be incomplete.

All sliding surfaces are frosted - even the sides of the clapper box - and, as most are still intact, the planer can have seen little use. The vice also appears to 'belong' to the machine, with the bolt holes lining up with the slots in the bed. The moveable jaw lock in grooves in the base of the vice, allowing the operator to set its position quickly and easily.

Included with the machine when found in a house-clearance sale where a number of original cutting tools, a number of them bearing the maker's name W. Marples & Sons with a "shamrock" trademark.

A larger Firth planer can be seen here. |

|

|

|

|

|

|  |

|

|

|

|

|

|

| Particularly elegant and delicate casting (American in quality) and, at the near end, can be seen the "inverted" V-ways to guide the carriage. Note the similarities to the Tom Senior Models Nos. 1 and 2 and also to the Hesketh-Walker. |

|

|

|

|

|

|

|

|

|

|  |

|

|

|

|

|

|

| On this model the designer took care to extend the cross-had ways to allow the machining on components wider than the table |

|

|

|

|

|

|

|

|

|

|  |

|

|

|

|

|

| Typical of its era the clapper box was lightly built. |

|

|

|

|

|

|  |

|

|

|

|

|

| Nuts and bolts from the pre-WW1 era can be recognised by their unnecessarily generous proportions |

|

|

|

|

|

|  |

|

|

|

|

|

|

| Tapered location pin for the clapper box |

|

|

|

|

|

|  |

|

|

|

|

|

|

|

|

| The hinged stop used to reverse the feed to the bridge-mounted toolpost |

|

|

|

|

|

|  |

|

|

|

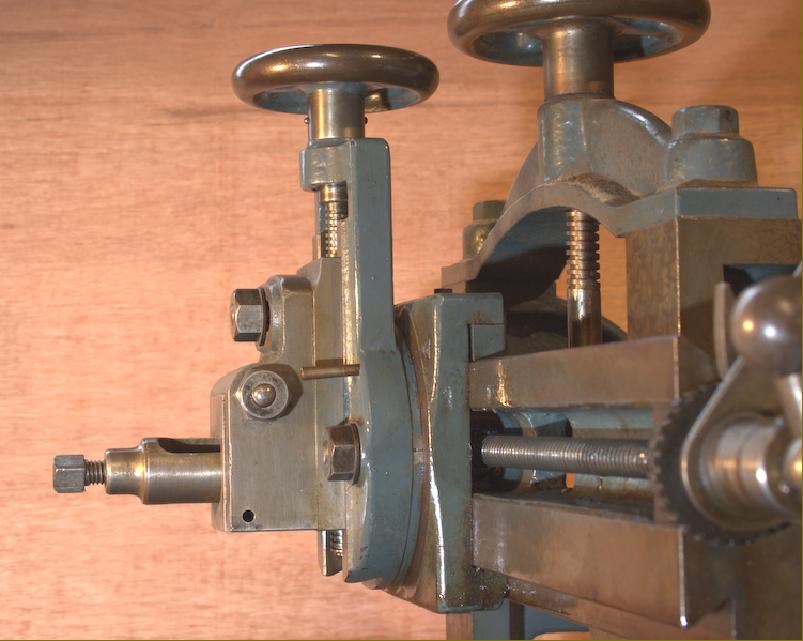

| Simple indexing mechanism used to move the cutting tool across the bridge |

|

|

|

|

|

|  |

|

|

|

|

| |

it's really nice blog and nice posting

ReplyDeleteWe manufacturers Heavy duty lathe machine, Roll turning lathe machine, Light duty lathe machine, Radial Drill, Shaper Machine and Hacksaw Machine.

This blog is very nice.Light duty lathe machine for use in different industries is offered by Navashu. Use of cutting-edge technology and quality raw material makes Light duty lathe machine reliable and highly durable.Light duty lathe machine.

ReplyDeleteI have one of these in operating/great condition..if you want more photos, let me know.

ReplyDeleteThank you for the information!

There isn't much out there...